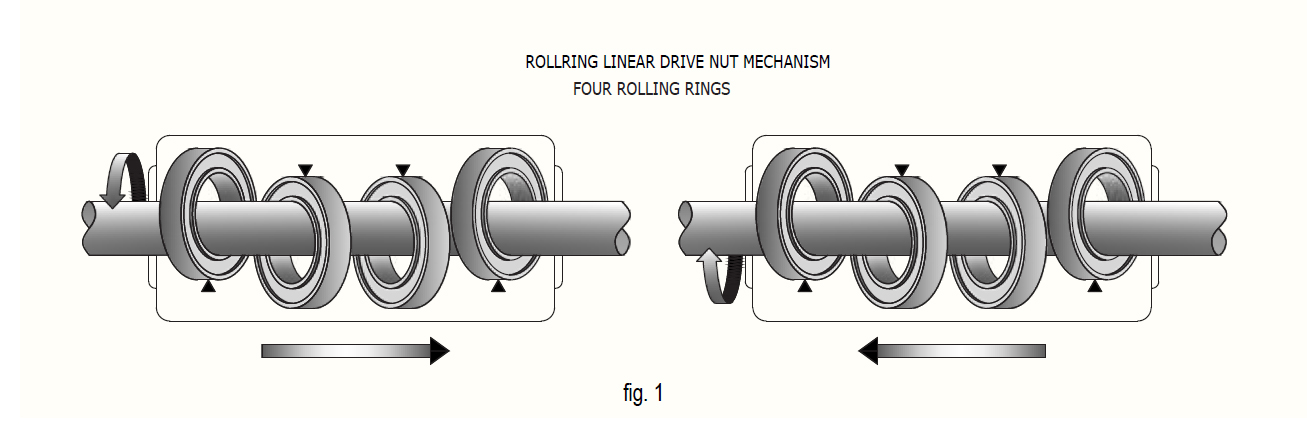

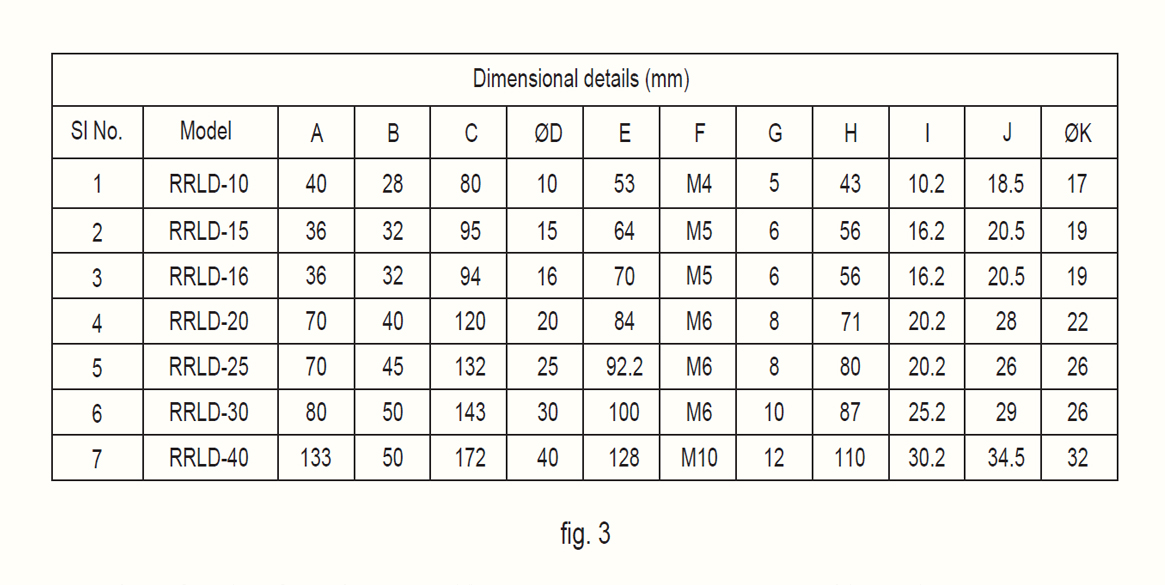

Pitch

Linear movement per shaft rotation, available in fixed values for both directions. Linear speed depends on shaft speed.

Side Thrust:

Maximum force that can be safely applied.

Optional Accessories

- Free Movement Lever (Release Lever): Allows disengagement of the linear drive nut from the shaft.

- Optional scrapers gently clean the shaft during motion, ensuring uninterrupted operation.

Selection of Drive Nut

When selecting a drive nut model, it's crucial to account for the various forces and factors that influence its performance. This selection process takes into consideration the cumulative effects of the associated assemblies being traversed, frictional load, linear speed, weight of the drive nut, max traverse length, and other parameters.

Maintenance

Minimal maintenance required; routine shaft lubrication with grease suffices.

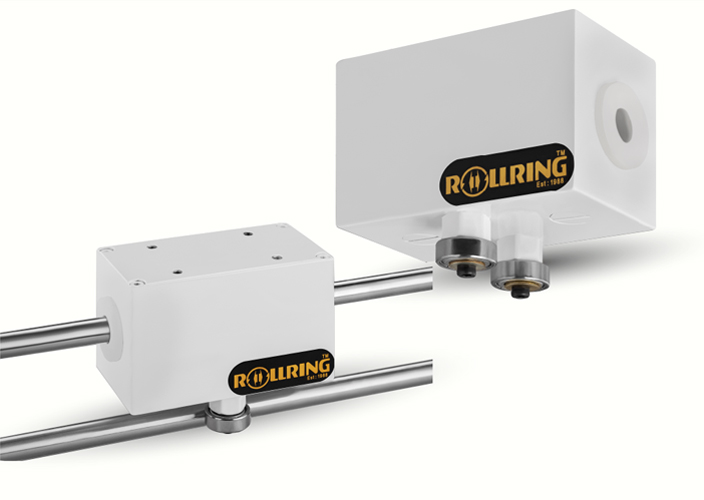

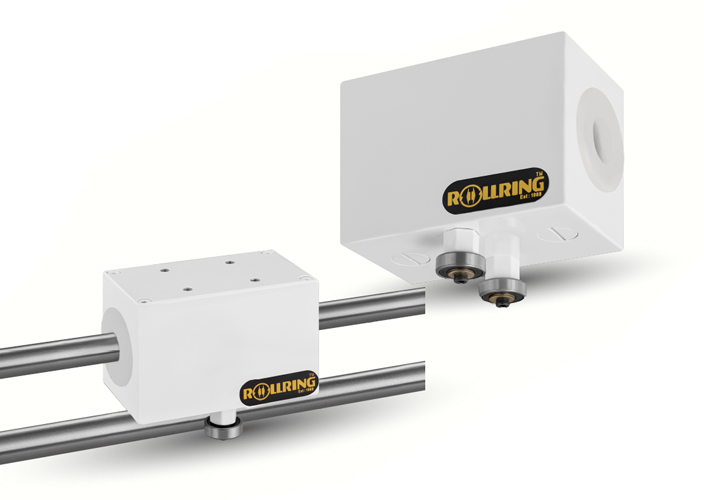

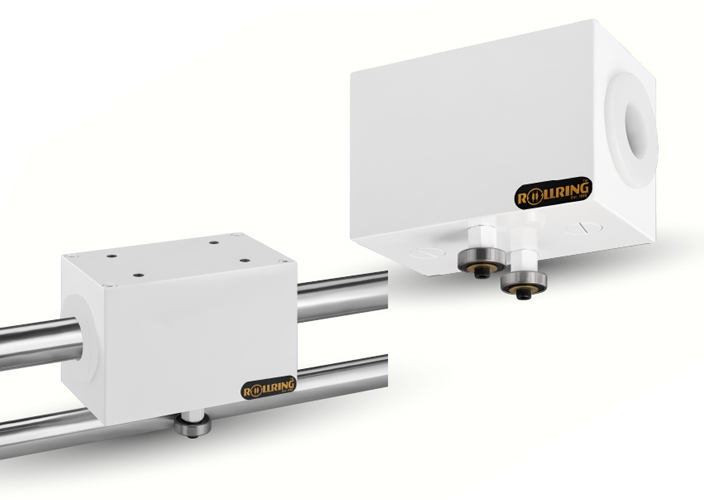

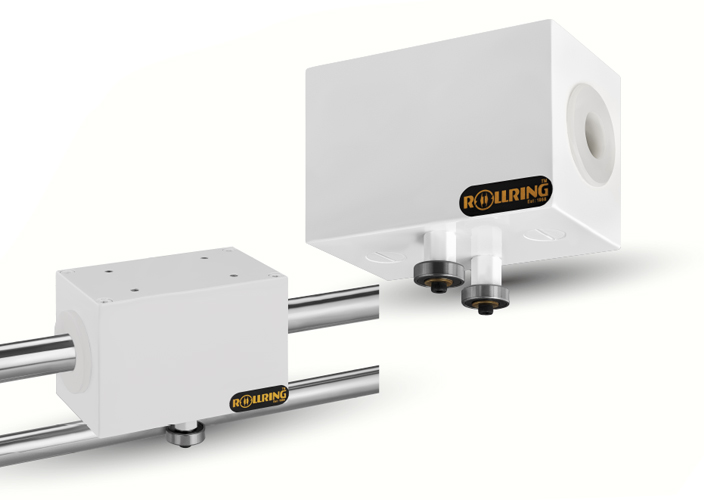

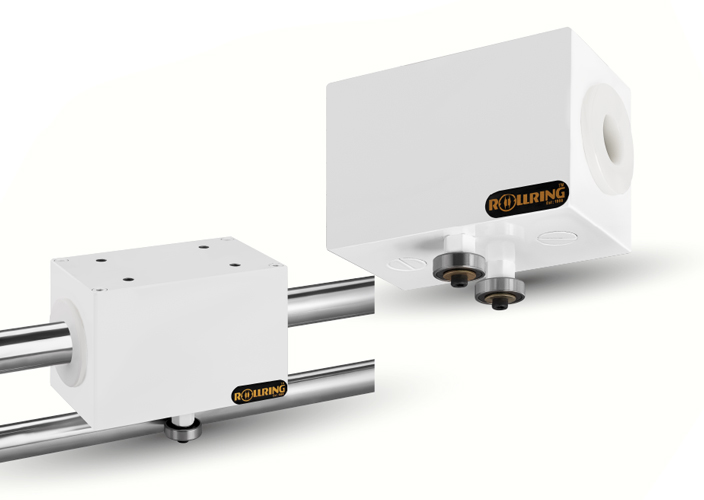

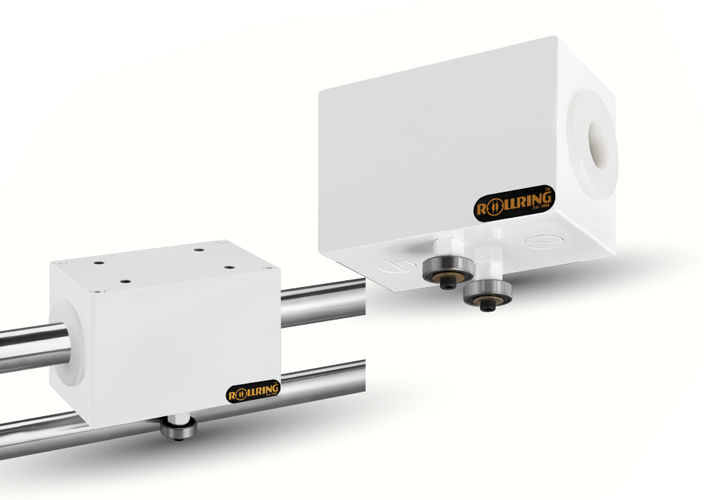

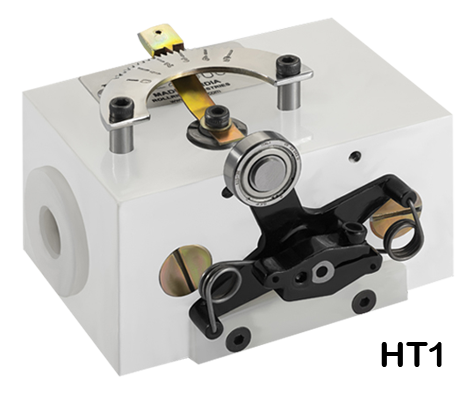

Drive Nut Assembly

Customizable to specific requirements, accounting for traverse length, guides, fixtures, load

carriers, and shaft specifications.

Recommended Shaft Attributes:

- High surface hardness

- Straightness

- Ground finish

- Material: C45

- Heat Treatment: High-Frequency Induction Hardening

- Hardness: HRC 58-62

- Surface Roughness: Polished Ra <= 0.8μ

- Shaft Straightness: Within 50μ per 300 mm

- Tolerance: g6

- Corrosion Protection: Hard Chrome

Guide Rod/Rail

Prevents linear drive nut rotation on the shaft, featuring two guide bearings.

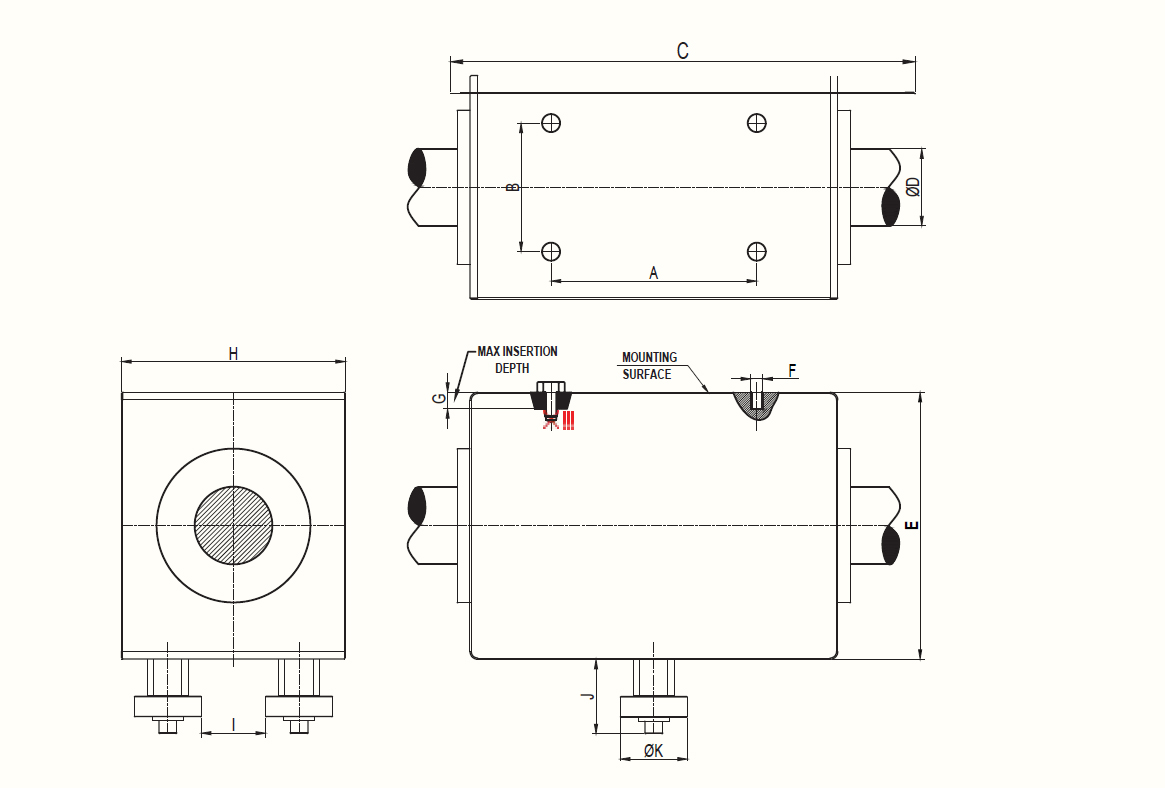

Assembling Linear Drive Nut and Shaft

Insert one end of the shaft into the nut and rotate.