Application : Bobbin is traversed with Rollring traverse unit and material to be wound is guided from a stationary guide roller stand.

Used Tension controlled layer winding of any material.

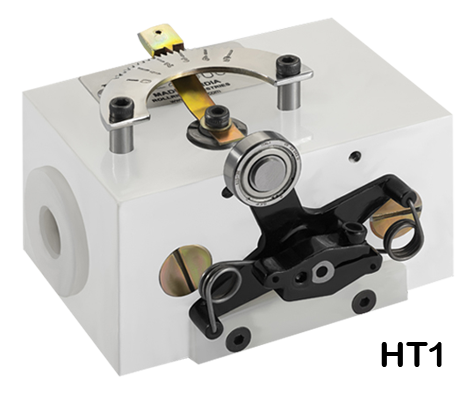

Rollring traverse assembly is provided for traversing the bobbin along with gear box and associated assembly, motor etc.

Bobbin Dimensions : To suit customer requirements

Maximum Flange diameter : 1000mm

Maximum Weight : 750Kg

We can also supply the machine with inbuilt collapsible bobbin

Bobbin loading : Pintle type between a head stock and tail stock or cantilever shaft type.

Bobbin Loading : We can also offer Shaft Type loading of bobbin on pintles.

Brake : Dynamic braking with AC drive and DBR

Drive : By an AC Motor with a reduction gear box

Drive Transmission : Timer belt

Machine Constructionx : The machine will be of sturdy design and robust construction. The Platform carrying the head stock, tail stock housing, traverse assembly, drive motor etc. will be traversing on a guide carrier with linear bearing and rail.

Traverse : By Rollring Traverse unit. Traverse unit is stationary and the shaft along with mounting brackets will be traversing. The pitch and stroke length can be finely adjusted.

Tensioning Roller stand : Material to be wound will be guided to bobbin from stationary tensioning roller stand with adjustable guide rollers

Length Counter :Electronic

Strip Guide Assembly : Guide assembly consists of a tensioning roller assembly with adjustable rollers, a guide arm with rollers to guide the strip, pressure pad etc. A swivelling type Guide arm is supported on a carrier with linear bearing for X-axis movement is provided. The position of the guide arm can be finely adjusted in Y-axis with a hydraulic cylinder and hand lever pump during winding as required.

Control Panelr : Control panel with Siemens / ABB make AC drive and accessories is provided.

Safety Guards : Provided