Application :Semi-automatic layer winding of insulated wire or rectangular conductor for the manufacture of transformer coil.

We can provide layer winding machine to suit your requirements of dimensions of coil to be manufactured, diameter of wire and size of rectangular conductor.

Accessories available : Adjustable former, Tensioning stand for wire, De-realer loading number of bobbins, Edge strip holder and Paper roller stand.

Wire diameter : 0.3mm to 6mm

Maximum Rectangular conductor size : 70mm2

Material : Copper or Aluminium

Maximum Coil height : 1500mm

Maximum Coil outside diameter : 1000mm

Coil Inside Diameter : According to your requirements

Maximum Coil Weight : 2000Kg

Shape of coil : Concentric circular

Head Stock : Consists of a heavy-duty Gear box of robust design. Shaft mounted on heavy duty bearings and provided with a face plate for loading the mandrel.

Mandrel Shaft : We provide shaft for loading the wooden former or an adjustable former. Shaft or mandrel is bolted to a face plate of head stock shaft and supported with the tail stock pintle. Drive plate and threaded nut provided on the shaft for loading the wooden former.

Tail Stock : Tail stock assembly is mounted on a swivelling arm or on a pedestal, movable with a handle. Tail stock pintlemovement with handle and locking arrangement.

Unloading of Finished Coil : Coil is removed easily with crane after opening the tail stock.

Drive : With AC Motor and areduction gear box

Drive Transmission :Timer belt or a duplexchain

Maximum Mandrel Speed : 400 RPM

Foot Switch : Machine operated with foot switch. Separate foot switch provided for Forward and Reverse operation.

Brake : Disc brake

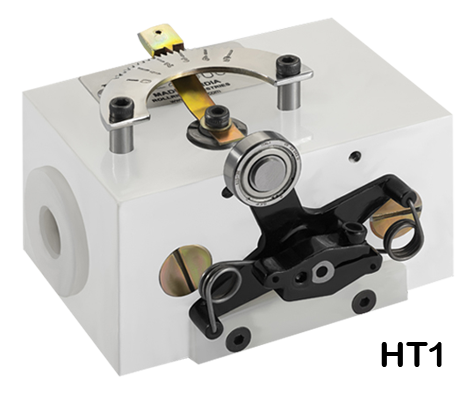

Traverse Assembly : Traverse assembly with a suitable model of Rollring traverse unit is provided for layer winding. The pitch can be finely adjusted to suit the diameter of wire or width of the conductor. The linear movement of traverse is synchronized with the mandrel speed. Traverse shaft drive is through a two-speed gearbox for fine adjustment of the pitch. Reversal will be instantaneous and automatic. Winding length can be finely adjusted. Guide assembly can be positioned suitably along the length of former with handle on traverse shaft after disengaging the drive with an electromagnetic clutch.

Guide Carriage : Guide carriage with LM block and rail is mounted on a machined plate. Wire guide pulley assembly or a tensioning roller assembly is mounted on the carriage. Carriage will be moving and supporting the Wire or Rectangular conductor with its guides along the length of the machine. Separate guide assembly is provided for wire and rectangular conductor, which can be easily interchanged.

Tensioning Roller Assembly : Tensioning roller assembly is provided for guiding the rectangular conductor. Will be suitable to guide required number of conductors for layer winding. It consists of 6 horizontal rollers, suitably assembled. Top rollers are adjustable with handle for tightening the conductor.

Alternatively, Air cylinder with pressure regulator is provided.

Guide assembly for wire : Consists of 4 pulleys, 1 pulley with pneumatically brake and 1 pulley mounted on an adjustable arm to guide the wire to the mandrel.

Control Panel : Control panel with an AC Variable frequency drive, and accessories. Machine is operated with 2 foot switches, one for forward and another for reverse rotation of the mandrel.

Mandrel : We can supply mandrel to suit minimum and maximum dimension of coil to be manufactured.

Diameter of the mandrel is manually adjustable with handle and can be locked after adjustment. 8 wooden segments are mounted on the mandrel with multiple radial and axial supports. Wooden segments will be polished and will be made of hard wood.We can provide any mandrel diameter range according to your requirement.

Maximum Length of segments : 2000mm

Number of Segment : Eight

Expansion Range : Expansion in each stage varies from 40 mm to 100mm depending on size of mandrel pipe. Add on segments are supplied to increase the diameter range.

Maximum Coil weight : 2000Kg

Head Stock : Consists of heavy-duty gear box of robust design. Shaft mounted on heavy duty bearings and provided with a face plate for loading the mandrel.

Mandrel Shaft : We can supply shaft for loading the wooden former or adjustable former. Shaft or the Mandrel is bolted to face plate of head stock shaft and supported with tail stock pintle. Drive plate and threaded nut provided on the shaft for loading wooden former.

Tail Stock : Tail stock assembly is mounted on a swivelling arm or on a pedestal movable with handle. Tail stock pintle movement with handle with locking arrangement.

Unloading of finished Coil : Coil is removed easily with crane after opening tail stock.

Mandrel Shaft : Shaft mounted on the head stock drive plate and the tail stock pintle is supplied for loading the former

Alternatively : Mandrel with adjustable wooden segments.

Mandrel : Diameter of mandrel is manually adjustable with handle and locked after adjustment. 8 wooden segments are mounted on the mandrel with multiple radial and axial supports. Wooden segments will be polished and will bemade of hard wood.

Diameter range : 100mm to 400mm

Number of Segment : Eight

Expansion Range in Each Stage : 40 mm to 100mm (depends on size of the former). Add on segments are supplied to increase the diameter range as required.

Brake : Disc brake

Optional Accessories

1) Tensioning Stand : Tensioning stand is provided for the wire. It consists of a stand with adjustable height, guide pulley, 1 braked pulley, tensioning arm with guide pulley, pneumatic control for tensioning arm and Braked pulley etc.

2) De-realer for Rectangular Conductor (Bobbin stand) : Motorized bobbin stand is provided for loading required number of bobbins with rectangular conductor. The bobbins are mounted one behind other at different height on shafts on fabricated structure. The entire structure is mounted on wheels and can be moved on rail mounted parallel to the mandrel. AC geared motor is provided for the operation with a push button. Proximity sensors are provided at end limit.

Maximum Number of Bobbins : 48

3) Full width insulation de-coiler

4) Derealer for edge strip