Application : For tension controlled winding of wire in bi-conical bobbin.

Bobbin Dimension : As per customer requirements.

Filled Weight : As per customer requirements

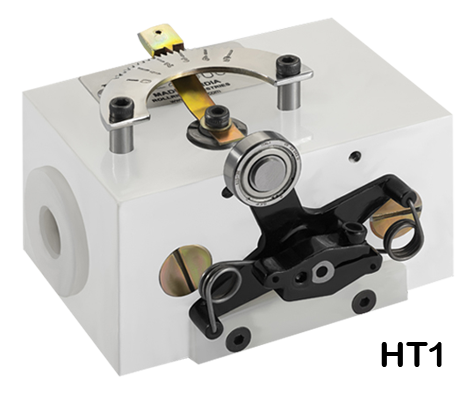

Bobbin Loading : Shaft type or between head stock and tail stock pintle. Tail stock housing is mounted on a swivelling arm. Pneumatically operated or screw type pintle movement can be offered.

Traverse Assembly : With Rollring Traverse unit. Traverse pitch can be adjusted very finely. Motorized reversal end limit control is provided. Minimum and maximum traverse length are set with proximity sensors. Taper winding is controlled with a small PLC and sensors provided for counting number of strokes. Wire guide pulley is mounted on a carrier with linear bearing and guide shaft.

Alternatively : We can offer traverse assembly with Ball screw driven by ac geared motor. Traverse Stroke Settings PLC control for taper winding. Traverse pitch Control: AC variable frequency drive provided

Brake : Electromagnetic brake/Disc brake

Length counter : Electronic

Drive :By AC motor with reduction gear box.

Drive transmission : Timer Belt

Speed and Tension Control : AC Variable frequency drive with accessories are provided .

Control panel : Control panel with ABB, AC variable frequency drive, PLC and accessories are supplied

Optional:

Capstan assembly : : Capstan assembly for pulling the wire from the coating line Drive: AC geared motor

Speed control: AC variable frequency drive