Application : Tension controlled off Line coating of FRP wire

Coating line consists of driven or non-driven Payoff, Dancer assembly, Extruder, Capstan assembly , Dancer assembly and Take-up.

We offer custom machines to suit our customer requirements.

Bobbin Dimensions and filled weight : As per customer requirements

Max Flange dia : 1200mm

Maximum Weight : 900 Kg

Wire Size : 0.4mm to 4.0mm

Line speed : As per customer requirement.

Maximum Line speed : 1000 Meters/Minute

Payoff (Unwinder)

Machine Construction : Machine will be of very sturdy design with Head stock, Tail Stock, Motor and Gear box mounted on a common frame.

Bobbin loading : Pintle type between head-stock and tail-stock

Head Stock : Head stock shaft with pintle and dive pulleys are assembled on a sturdy housing with heavy duty bearings.

Tail stock : Tail Stock shaft with pintle is assembled on a sturdy housing with pneumatically operated tail stock. Alternatively we offer screw type adjustments with handle for movement of pintle

Loading / Unloading of Bobbin : Motorized with AC Geared motor

Driven type pay off AC Motor is provided. AC Variable frequency drive provided for speed and tension control.

Drive Transmission : V-Belt

Speed and Tension Control : Dancer assembly with Linear Potentiometer provided. Dancer assembly regulates un-winding speed maintaining the line speed and tension uniform.

Horizontal or Vertical type Dancer assembly can be offered. Dancer pulleys will be ceramic coated.

Non Driven type pay off : Disc brake with Precision air pressure regulator is provided for tension control. Dancer assembly is provided without linear potentiometer.

Brake : Disc Brake

Operating Desk : Provided

Safety Guard and Cover : Safety covers provided for all drives

Sliding door : Optional

Extruder : Optional. We can offer extruder with all accessories to suit customer requirements.

Customer can directly purchase extruder as we are not manufacturing extruder

Capstan Assembly : Capstan assembly provided for pulling the wire from payoff through the extruder at the required line speed.

Centre height : 1000mm

Drive : AC Geared Motor

Speed Control : BY potentiometer

Take-up(Winder)

Machine Construction : Machine will be of very sturdy design with Head stock, Tail Stock, Motor and Gear box mounted on a common frame.

Bobbin loading : Pintle type between head-stock and tail-stock

Head Stock : Head stock shaft with pintle and dive pulleys are assembled on a sturdy housing with heavy duty bearings.

Tail stock : Tail Stock shaft with pintle is assembled on a sturdy housing with pneumatically operated tail stock. Alternatively we offer screw type adjustments with handle for movement of pintle

Loading / Unloading of Bobbin : Motorized with AC Geared motor

Driven type pay off AC Motor is provided. AC Variable frequency drive provided for speed and tension control.

Drive Transmission : V-Belt

Speed and Tension Control : Dancer assembly with Linear Potentiometer provided. Dancer assembly regulates un-winding speed maintaining theline speed and tension uniform.

Horizontal or Vertical type Dancer assembly can be offered. Dancer pulleys will be ceramic coated.

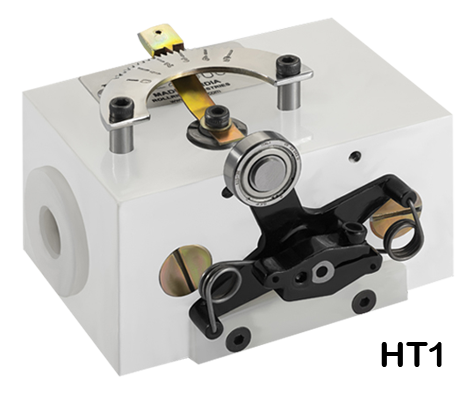

Traverse Assembly : Traverse assembly withRollring Traverse unit provided.

Traverse : Pitch and stroke length can be adjusted very finely adjusted. Traverse speed is synchronized with bobbin speed. Ceramic Wire Guide pulley is provided

Length Counter : Electronic

Drive : With AC Motor with Variable frequency drive.

Tension and speed Control : Linear potentiometer in the dancer assembly maintains line speed in synchronisation with capstan speed and uniform tension.

Drive Transmission : V-Belt

Control Panel : Control Panel with ABB /Siemens or any reputed make AC variable frequency drive and accessories are provided

Operating desk : Provide

Brake : Disc Brake

Safety Guard and Cover : Safety covers provided for all drives.

Sliding door : Optional