Application :Motorized Tension controlled take up for FRP wire comprising of multiple independently controlled winders.

We offer Take up to suit customer requirements of loading different sizes of bobbin, wire diameter and line speed.

Machine Construction : The bobbins are mounted in line, one behind the other with shafts mounted on a fabricated frame support comprising of individual motors with tension and speed control, traverse assembly and an electronic counter for each winding head. The structure will have proper grouting arrangement. The bobbin will be held with a drive plate and pin on one side and a tapered Pintle and a lock nut with handle on the other side. Hinged door or cover will be provided. Lighting will be provided inside machine frame.

Double decker Take up : We offer double decker take up for smaller sizes of bobbins up to flange diameter up to 630 mm with bobbin mounted in two rows one above the other. We also offer winders for loading 800mm flange diameter bobbin in bottom row and 630mm flange dia bobbin on top row.

Each Take up is provided with individual Motor, Traverse assembly, Tension and Speed control system and an electronic counter.

Spool holding : Shaft type

Bobbin Dimension and filled weight : To suit customer requirements

Maximum Flange dia : 1200mm

Maximum Weight : 900 Kg

Maximum Wire diameter : 6mm

Minimum Wire diameter : 0.4mm

Maximum Winding Speed : 15 meters / minute

Drive : Torque motor with reduction gear box.

Tension and Speed Control : With three phase enclosed type dimmer stat provided to vary voltage applied to torque motor. Take up speed is automatically synchronized and the tension will be uniform throughout the winding.

Drive Transmission : Chain Drive

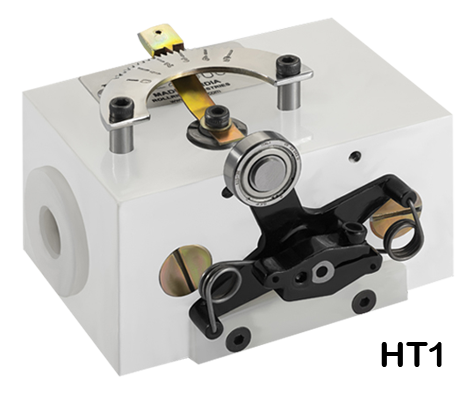

Traverse Assembly : With Rollring Traverse unit. Winding pitch and stroke length can be adjusted very finely. Traverse speed is synchronized with the bobbin speed. Ceramic wire guide pulley is provided.

Wire Guide Arrangement : Guide pulleys and guide rollers will be provided to ensure smooth passage of wire to different bobbins.

Length counter : Electronic