Application :Tension controlled Rewinding of FRP or ARP wire.

We offer the Rewinding line with driven type or Non driven type pay off.

Machine Description : Rewinding line consist of Payoff, Dancer assembly, and Take up.

Rewinding Line is offered to suit customer requirements of bobbin dimensions, wire size and speed.

Bobbin Dimensions and filled weight : As per customer needs

Maximum Flange diameter : 1200 mm

Maximum Weight : 900 Kg

Wire Size range : 0.4mm to 6.0mm

Maximum Line speed : 1000 Meters/Minute

Pay-off stand

Bobbin loading : Pintle type between ahead stock and a tail stock.

Head Stock : Head stock shaft with pintle and dive pulleys are assembled on a sturdy housing with heavy duty bearings.

Tail stock : Tail stock shaft with pintle is assembled on a sturdy housing with heavy duty bearings. We offer pneumatically operated or screw operated tail stock

Loading and Unloading of Bobbin : Motorized with AC geared motor or Alternatively Adjustable Ramp.

Drive (Applicable only for Driven Payoff) : With AC motor

Drive Transmission : V Belt

Speed and Tension Control Dancer assembly

Driven Pay off : Speed is controlled with linear potentiometer and AC variable frequency drive.

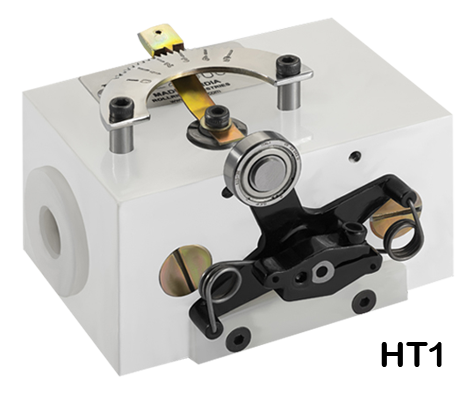

Non-driven payoff : Disc brake with precision air pressure regulator.

Brake : Disc Brake

Operating Desk : Provided

Safety Guards and Covers : Safety covers provided for all drives

Sliding cover : on the front side offered on request.

Takeup Stand

Bobbin loading : Pintle type between ahead stock and a tail stock.

Head Stock : Head stock shaft with pintle and dive pulleys are assembled on a sturdy housing with heavy duty bearings.

Tail stock : Tail stock shaft with pintle is assembled on a sturdy housing with heavy duty bearings. We offer pneumatically operated or manually operated tail stock.

Loading and Unloading of Bobbin : Motorized with AC geared motor or Alternatively Adjustable Ramp.

Bobbin loading : Drive

Drive Transmission : V Belt

Traverse Assembly : With of Rollring Traverse unit. Traverse Pitch and stroke length can be finely adjusted. Traverse speed is automatically synchronized with bobbin speed. Guide carrier with 4 linear bearings and 2 guide shafts are provided for mounting ceramic wire guide pulley.

Length Counter : Electronic

Drive : By AC Motor.

Speed Control : With AC variable frequency drive, speed can be very finely adjusted with a potentiometer. Encoder provided to sense and maintains the line speed set constant throughout the winding.

Drive Transmission : V Belt

Control Panel : Control Panel with ABB/Siemens or similar reputedmake AC variable frequency drive and its accessories is provided

Operating desk : Provided

Brake : Disc Brake

Safety Guards and Covers : Safety covers provided for all drives.

Sliding door on the front side offered on request.

Pneumatic components All pneumatic components will be of Festo Make.

Dancer Assembly : Horizontal or vertical typedancer assembly is available.

Dancer assembly consists of five numbers ceramic coated pulleys. Two number pulleys are movable and mounted on a carrier with linear bearing Air cylinder and an air pressure regulator is provided for tension control.

Linear potentiometer : Provided for driven payoff stand

Four Pulley Stand : Consists of four number ceramic pulleys mounted on a stand. Two number pulleys are adjustable Vertical rollers are provided at the inlet and the outlet. Suitable printer can be installed on the stand.